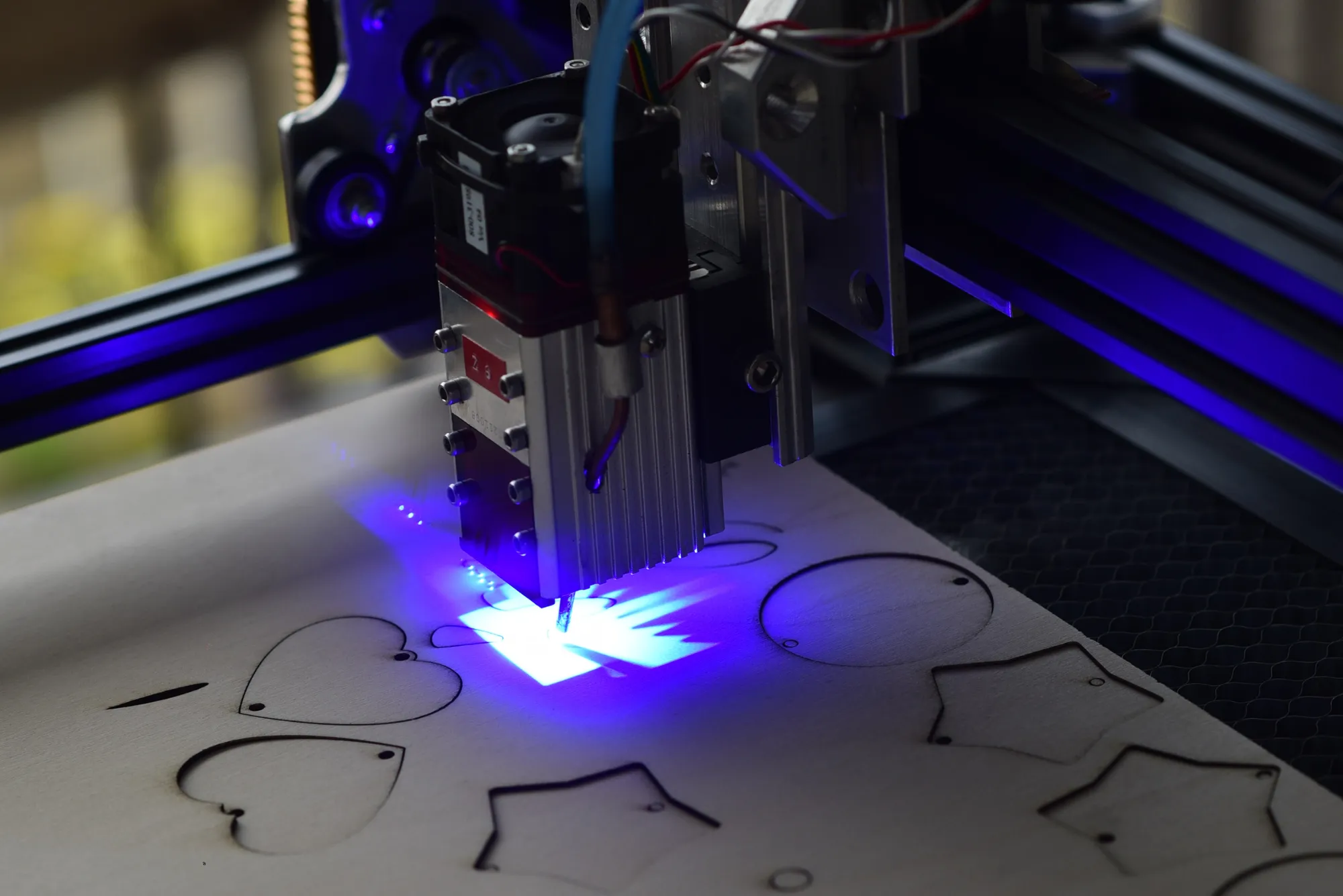

Maintaining a laser engraving machine is crucial for ensuring its longevity, accuracy, and efficiency. Proper maintenance not only helps in extending the life of the machine but also ensures that it continues to produce high-quality engravings. In this guide, we will discuss the essential steps and practices that can help you keep your laser engraving machine in optimal condition.

Regular Cleaning of the Laser Engraving Machine

One of the most important aspects of maintaining a laser engraving machine is regular cleaning. The process of engraving generates a lot of dust, debris, and residue, which can accumulate on the machine’s components, affecting its performance.

Cleaning the Lens and Mirrors

The lens and mirrors are critical components of a laser engraving machine as they direct and focus the laser beam. Over time, they can become dirty or smudged, which can reduce the intensity of the laser and affect the quality of the engraving.

- Frequency: Clean the lens and mirrors at least once a week, or more often if you use the machine frequently.

- Method: Use a soft, lint-free cloth or specialized lens-cleaning tissue. Avoid using harsh chemicals or abrasive materials as they can damage delicate surfaces.

Clearing the Exhaust System

The exhaust system in a laser engraving machine is responsible for removing smoke and fumes generated during the engraving process. A clogged or dirty exhaust system can lead to poor air quality and even pose a fire hazard.

- Frequency: Inspect and clean the exhaust system every month.

- Method: Remove and clean the filters, and ensure that the ducts are free from obstructions.

Cleaning the Work Area

The work area of the laser engraving machine should be kept clean to prevent debris from interfering with the engraving process.

- Frequency: Clean the work area after every engraving session.

- Method: Use a vacuum or a soft brush to remove any dust or debris.

Routine Inspection of the Laser Engraving Machine

Routine inspection is key to identifying potential issues before they become serious problems. Regularly inspecting the various components of the laser engraving machine can help you catch wear and tear early.

Checking the Laser Tube

The laser tube is the heart of the laser engraving machine, and its performance directly affects the quality of the engraving. Over time, the laser tube can degrade, leading to reduced power and efficiency.

- Frequency: Inspect the laser tube every three to six months.

- Signs of Wear: Look for any signs of reduced power or inconsistent engraving results.

- Action: If the laser tube shows signs of wear, consider replacing it to maintain optimal performance.

Inspecting the Belts and Bearings

The belts and bearings in a laser engraving machine are responsible for the smooth movement of the laser head. Worn or damaged belts and bearings can lead to inaccurate engravings and may cause the machine to malfunction.

- Frequency: Inspect the belts and bearings every month.

- Method: Check for signs of wear, such as fraying belts or noisy bearings. Replace any damaged parts promptly.

Verifying the Calibration

Calibration is essential for ensuring that the laser engraving machine produces accurate and precise engravings. Over time, the machine may lose calibration due to regular use or accidental bumps.

- Frequency: Verify the calibration every three months.

- Method: Use a calibration test pattern to check the accuracy of the machine. Adjust the settings as necessary to ensure precision.

Lubrication of Moving Parts

Lubrication is an important part of maintaining the laser engraving machine. Proper lubrication ensures that the moving parts operate smoothly, reducing wear and tear and preventing mechanical failures.

Lubricating the Rails and Bearings

The rails and bearings are crucial for the smooth movement of the laser head. Without proper lubrication, these components can become stiff, leading to jerky movements and inaccurate engravings.

- Frequency: Lubricate the rails and bearings every three months.

- Method: Use a high-quality lubricant recommended by the manufacturer. Apply a small amount to the rails and bearings, and move the laser head back and forth to distribute the lubricant evenly.

Oiling the Motors

The motors in a laser engraving machine should be oiled regularly to ensure they run smoothly and efficiently.

- Frequency: Oil the motors every six months.

- Method: Apply a few drops of motor oil to the designated oil ports, as per the manufacturer’s instructions.

Software and Firmware Updates

Keeping the software and firmware of your laser engraving machine up to date is essential for maintaining its performance and ensuring compatibility with the latest technology.

Updating the Software

The software that controls your laser engraving machine is constantly being updated to fix bugs, improve performance, and add new features.

- Frequency: Check for software updates every month.

- Method: Visit the manufacturer’s website or use the built-in update feature to download and install the latest version of the software.

Firmware Upgrades

The firmware is the software that runs on the machine itself. Like the control software, the firmware may also receive updates that improve performance or add new functionality.

- Frequency: Check for firmware updates every six months.

- Method: Follow the manufacturer’s instructions to download and install firmware updates.

Environmental Considerations for Your Laser Engraving Machine

The environment in which you operate your laser engraving machine can have a significant impact on its performance and longevity. Factors such as temperature, humidity, and cleanliness should be carefully controlled.

Maintaining Optimal Temperature

The laser engraving machine should be operated in a room with a stable temperature to prevent overheating or condensation.

- Temperature Range: Keep the machine in an environment with a temperature range of 20-25°C (68-77°F).

- Cooling System: Ensure that the cooling system is functioning properly to prevent the laser tube from overheating.

Controlling Humidity Levels

High humidity can lead to condensation, which can cause short circuits and damage the electronic components of the laser engraving machine.

- Humidity Range: Maintain a humidity level of 40-60% in the room.

- Dehumidifiers: Use a dehumidifier if necessary to control humidity levels.

Ensuring a Clean Environment

A clean environment is essential for preventing dust and debris from entering the laser engraving machine and causing damage.

- Air Filtration: Use air filters to reduce the amount of dust in the room.

- Regular Cleaning: Keep the room clean by regularly vacuuming and wiping down surfaces.

Proper Storage and Handling of Materials

The materials you use with your laser engraving machine should be stored and handled properly to ensure the best engraving results and to prevent damage to the machine.

Storing Materials Correctly

Different materials require different storage conditions to maintain their quality.

- Wood: Store in a dry place to prevent warping.

- Acrylic: Keep away from direct sunlight to avoid discoloration.

- Metal: Store in a moisture-free environment to prevent rusting.

Handling Materials with Care

Proper handling of materials is essential to avoid damaging the laser engraving machine or the material itself.

- Placement: Ensure that the material is placed correctly in the work area to avoid misalignment.

- Secure the Material: Use clamps or other securing methods to hold the material in place during engraving.

Troubleshooting Common Issues with Laser Engraving Machines

Even with regular maintenance, you may encounter issues with your laser engraving machine. Knowing how to troubleshoot common problems can save you time and prevent damage to the machine.

Laser Not Engraving Properly

If the laser is not engraved properly, the issue could be related to the lens, mirrors, or laser tube.

- Solution: Clean the lens and mirrors, and check the laser tube for signs of wear. If the problem persists, consider recalibrating the machine.

Inconsistent Engraving Quality

Inconsistent engraving quality can be caused by a number of factors, including misalignment, dirty components, or software issues.

- Solution: Check the alignment of the laser head, clean the machine, and ensure that the software settings are correct.

Machine Not Powering On

If the laser engraving machine is not powered on, the problem could be related to the power supply, wiring, or internal electronics.

- Solution: Check the power supply and wiring for any issues. If the problem is not obvious, consult the manufacturer or a professional technician.

Maintaining a laser engraving machine requires regular cleaning, inspection, lubrication, and updates. By following the steps outlined in this guide, you can ensure that your machine remains in top condition, producing high-quality engravings for years to come. Proper maintenance not only extends the life of the machine but also enhances its efficiency and performance, making it a valuable tool for your engraving needs.